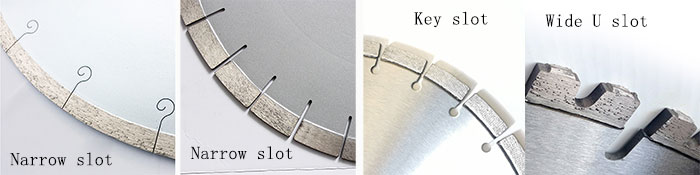

The distance or space affect the diamond disc cutting performance. Different blade slot and segment quantity will decide the distance among the diamond segments.

Narrow slot cores:distance between diamond segments is 1/16" or less. Narrow slot is specified a smooth cutting which is essential as in cutting marble tile, glass and ceramic materials, porcelain. The cutting action will be smoother than the continuous rim diamond disc with the bonus of increase disc life.

Standard Slot Blade:key slot: typically have 1/16" to 3/16" spacing between diamond segments. This recommended for general purpose cutting on materials where chipping and smooth surface finish is not very important. Key slot/medium distance will tend toward free, fast, cutting efficiency and provide better circulation of coolant. The key slot or standard slot is adopted by the stone diamond cutting disc, such as granite diamond cutting disc.

Wide Slot Blade:typically have slot width 5/16" to 3/8" and segment spacing to 1/2" or more. This type provides maximum chip removal and coolant circulation and reduces further the contact area. The wide slot diamond cutting disc is excellently suited to soft, loosely bonded, abrasive materials. Such as asphalt diamond cutting disc, wall cutting disc.

Z-LION (short for Xiamen ZL Diamond Technology Co., Ltd.) is a professional manufacturer of diamond tools in Xiamen, China. Established in 2002 and listed in New Third Board as a public company (stock code: 831862) in 2015. Quality, Efficiency, Innovation and Integrity is our aim and also our culture.

Z-LION have been engaged in developing and manufacturing diamond tools for concrete floor polishing since its establishment. Products include metal bond grinding pads for all kinds of floor grinders, resin bond polishing pads for wet and dry polishing, transitional polishing pads, PCDs, bush hammers, cup wheels, edge and corner polishing pads, sponge polishing pads, quick change adapters etc.

Z-LION attach much importance to innovation. We are honored as” National Intellectual Property Advantage Enterprise”, “Fujian Innovative Enterprises”. We own 63 of domestic and international patents. We are setter of “Diamond Flexible Polishing Pads Industrial Standard”.

Z-LION always do our best to keep close to customers. We have attended more than 100 exhibitions all over the world. Face to face meeting with customers in the exhibitions helped us to find out which kind of diamond tools will make polishing more efficient, so that we can keep updating our existing products and developing new products. Our products are loved by our customers especially in Europe, North and South American, Australia and Middle East.